Plastic Injection

Mould Design and Project Management

✓ Established in 2014

✓ 3500 m² Closed 1000 m² Open Area

✓ White Collar: 12 Blue Collar: 73

✓ 1500 tonnes/year raw material processing

✓ Powerful References

✓ Mould manufacturing

✓ 70% Automotive 30% Air conditioning

✓ Between 100-700 tonnes capacity 20 robotic machines

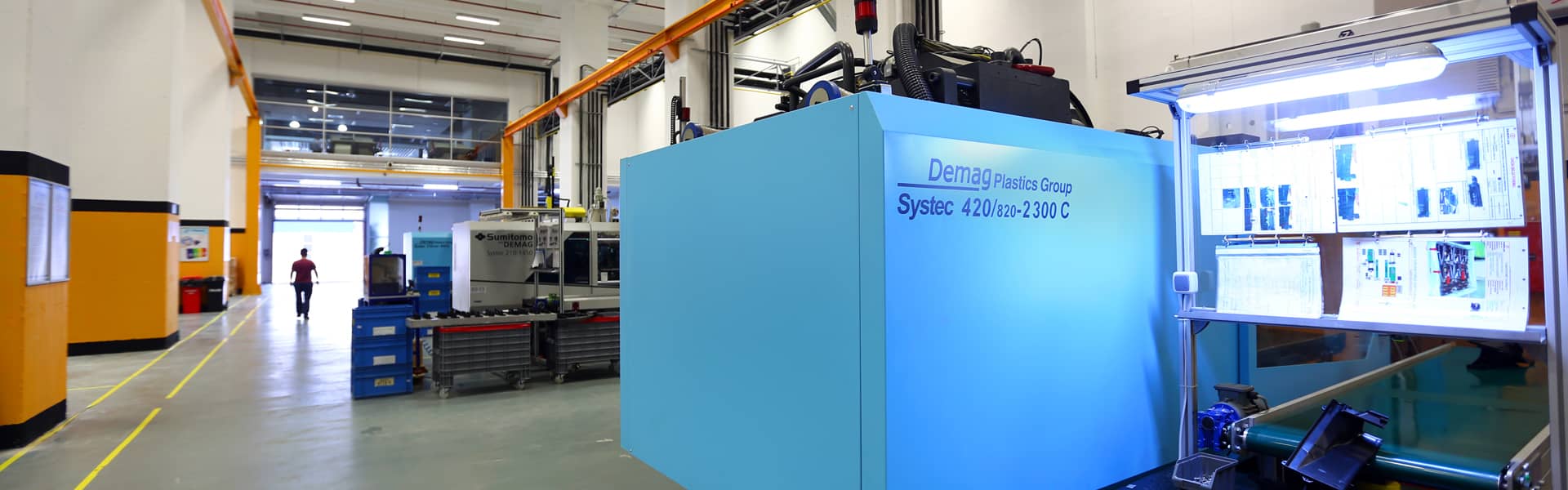

There are 20 injection machines with a capacity of 100 tons to 700 tons in our machine park. 4 of them are electric injection machines that produce better quality output by applying mass production and controlled power. All of our machines produce with robots.

Plasma Plastik uses the INFOR ERP Enterprise Resource Planning Management System to manage all production and non-production data in an efficient and integrated structure. Real-time Q2 Data Collection System integrated with ERP is used in the production area.

As Plasma Plastik, we also provide mould design, manufacturing and modification services. Periodic measurements are performed 24 hours / 3 shifts by our quality assurance technicians.

In our quality department, we carry out density test, flowability test (MFI), additive rate test (Ash Determination Test), colour measurement, 2D dimensional measurement (Caliper, Danchi, Triangle Ruler, Radius Gauge, Sentile Set), precision weight measurement, microscope camera measurement and surface roughness measurement.